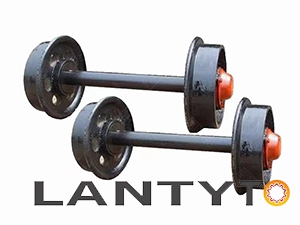

φ300*600 Mining Cart Wheel Sets

Description:600 Gauge Mining Cart Wheel Sets Diameter 250 Mining Cart Wheel Sets Wear Resistant and Durable

600 Gauge Mining Cart Wheel Sets are suitable for 600 gauge track.

Features:

600 gauge Mining Cart Wheel Sets has wheel rim on the inner side, and there is a certain clearance between wheel rim and rail. The tread surface of the wheel and rail contact is made into a cone, so as to keep the wheel pair in the running along the track to keep the centre, reduce the mechanical grinding, and reduce the running resistance.

600 Gauge Mining Cart Wheel Sets Common Failures and Causes

1, poor sealing. At present, a variety of old mining cars in coal mines are still widely used, and the use of labyrinth plus wool felt structure of the wheelset sealing treatment, this treatment, on the one hand, can not effectively prevent the water immersion, on the other hand, grease is prone to leakage. In the process of selecting lubricating grease, if the choice is not appropriate, its mechanical stability, water resistance, low temperature resistance and so on will be weakened to different degrees.

2, 600 gauge mine car wheel pair bearing abnormal wear. For the mine car, its bearings are usually used ordinary tapered roller bearings, the advantages of this bearing is a strong bearing capacity, and axial thrust capacity is relatively high, and its shortcomings are mainly manifested in the performance of anti-card performance is relatively weak. This bearing in the process of use, once immersed in the coal mud water, will block the bearing pipe, and then to a certain extent to destroy the lubricity of the bearing.

3, 600 gauge mine wheel on abnormal wear. Mine wheels in the running process, if the lack of lubrication, in this case will increase the sliding friction, which will lead to a further increase in wear between the mine wheels; if the mine car running track there are more curves, in this case the same will increase the wear of the wheels. When the mine car running in the curve, its centrifugal force, gravity of the combined force can not be perpendicular to the track surface, so there will always be centrifugal force. Under the action of centrifugal force, after running for a period of time, the negative deviation and positive deviation of the track gauge at the bend will increase, and when the mine car is driven from the standard track, the wheels will slide outward laterally, which will lead to accidents.

4, the mine car moves frequently, increasing the difficulty of dealing with faults, and no regular maintenance, often running with disease, the whole transport line is often blocked. For most mines, due to the lack of a sound mine car maintenance management system, which is difficult to carry out timely maintenance of mine cars, and maintenance personnel and maintenance teams are often replaced, also increasing the difficulty of mine car maintenance management.

Mine car is a coal mine transport in a large number of maintenance and transformation of a number of equipment, and the wheel is an important part of the mine car, both walking mechanism, but also load-bearing institutions. In the mine car damage, wheel pair damage is serious. The proportion of mine car damage caused by wheel pair failure is up to 70% or more. Therefore, it is of great significance for coal mine production to analyse the common failures of the wheel pairs, strengthen the maintenance and management of the mine cars, improve the reliability and service life of the wheel pairs, prolong the service life, maintain the turnover capacity, and reduce the production cost.

Related Products